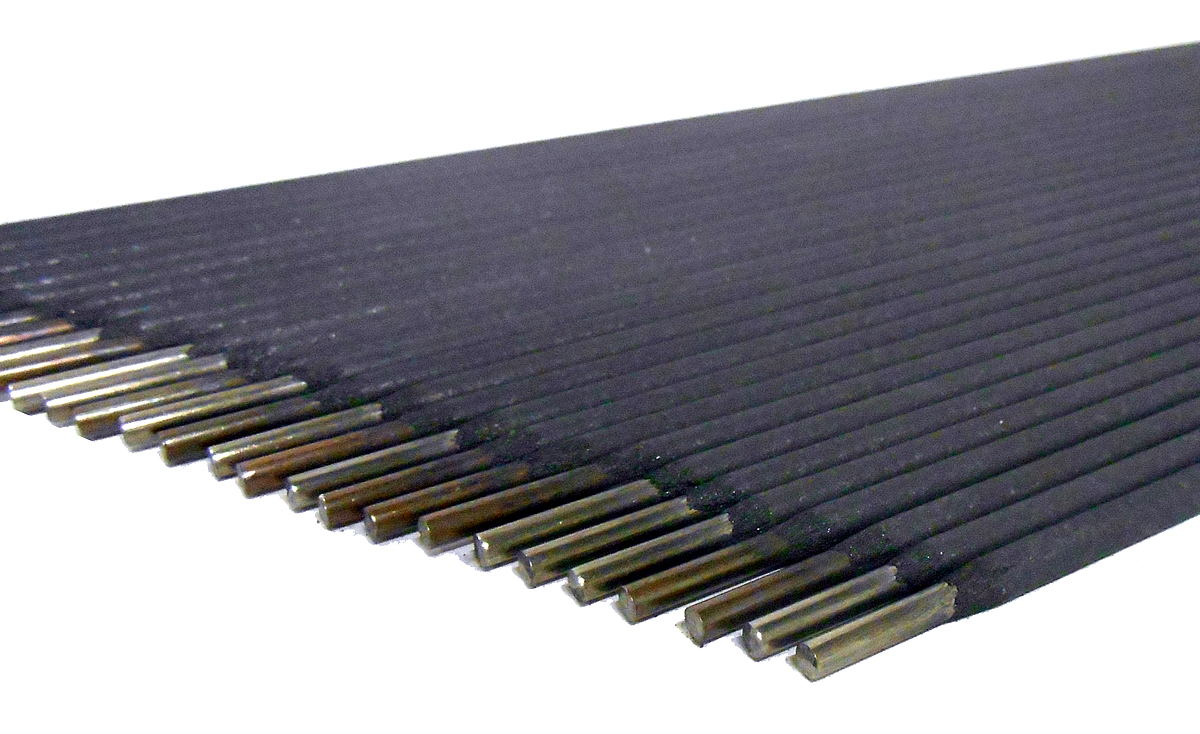

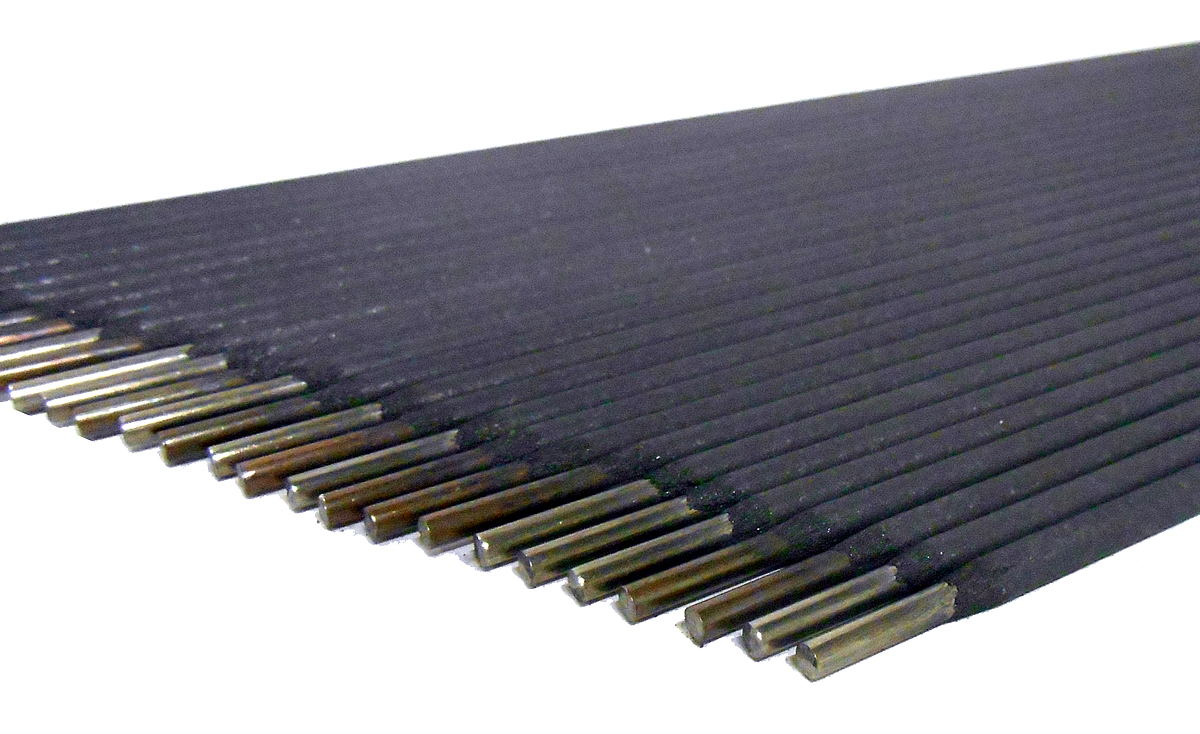

The first thing to figure out is what kind of welding rods and what size of welding rods to use. If you have nice new 1/8" material, I would go with 3/32" 7018 rods. If you have old rusty painted up 14 gauge, I might be inclined to use 1/8" or 3/32" 6011 rods. You might ask me, why don't you just grind the rust off? Well if it's just surface rust go ahead, but if it's pitted out you will grind all the material away before you get it clean. Not only that, but if you are just doing a quick repair job on something, just weld it. Chances are, if the material is that bad the weld will far out last the rest of the material anyway. Back to my point, 6011 is the rod I will pick anytime. It allows you to move a lot faster than 7018's will.

The 2 most common ways of starting your arc are by tapping and scratching your welding rod to the steel. Scratching seems to be the most natural way used by beginners.

Preheated welding may be easily carried out - notably for small and manageable objects. While welding the cast iron without preheating, this can be very important the operator has good control over the welding gun and make the welds as small as possible.

Keeping these points in mind, nghiep vu ke toan an effective purging process can be executed. The next step is tacking. One should get the tape off the tack to enable it to cool and re-tape it again. The process should be carried out 180 degrees apart.

Welding equipment that performs this type of welding is called as arc welders. Arc welders are machines that create an electrical current in the shape of an arc. This current can reach thousands of degrees in temperature, and it melts any type of metal. While arc welding may not be as common now as it used to be due to new forms of welding, it has a variety of uses and Arc welders used to be expensive tools that were available only to large companies or top tradesmen. Over the years, however, arc welders have become much more affordable. Smaller tradesmen and hobbyists can now enjoy the convenience of having their own arc welder. Whether you want to fix metal items around the house or restore a classic car, an arc welder can make the job easier.

TIG welders are also known as Heli arc or GTIG, (gas tungsten inert gas), welders. This system while really an advanced arc welder also uses a machine to produce an electrical current. A ground wire is also used. The current is again passed through a wire but the difference at the business end of this wire is the secret that makes this system work.

Extra care should be taken when running the root pass because If the root pass has good fusion and is water tight, the rest of the welding is just formality especially when welding pipe. Make sure the joint is good and hot and you are comfortable during the weld. Comfort means control.

Última modificação em

The 2 most common ways of starting your arc are by tapping and scratching your welding rod to the steel. Scratching seems to be the most natural way used by beginners.

Preheated welding may be easily carried out - notably for small and manageable objects. While welding the cast iron without preheating, this can be very important the operator has good control over the welding gun and make the welds as small as possible.

Keeping these points in mind, nghiep vu ke toan an effective purging process can be executed. The next step is tacking. One should get the tape off the tack to enable it to cool and re-tape it again. The process should be carried out 180 degrees apart.

Welding equipment that performs this type of welding is called as arc welders. Arc welders are machines that create an electrical current in the shape of an arc. This current can reach thousands of degrees in temperature, and it melts any type of metal. While arc welding may not be as common now as it used to be due to new forms of welding, it has a variety of uses and Arc welders used to be expensive tools that were available only to large companies or top tradesmen. Over the years, however, arc welders have become much more affordable. Smaller tradesmen and hobbyists can now enjoy the convenience of having their own arc welder. Whether you want to fix metal items around the house or restore a classic car, an arc welder can make the job easier.

TIG welders are also known as Heli arc or GTIG, (gas tungsten inert gas), welders. This system while really an advanced arc welder also uses a machine to produce an electrical current. A ground wire is also used. The current is again passed through a wire but the difference at the business end of this wire is the secret that makes this system work.

Extra care should be taken when running the root pass because If the root pass has good fusion and is water tight, the rest of the welding is just formality especially when welding pipe. Make sure the joint is good and hot and you are comfortable during the weld. Comfort means control.